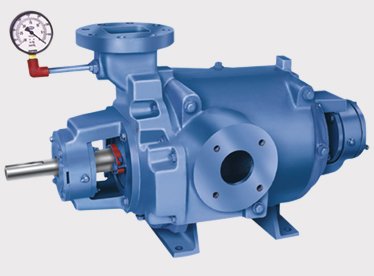

Nash* 904 Vacuum Pump: Rebuilt Units, Replacements & Parts

Nash* 904 Vacuum Pump: Rebuilt Units, Replacements & Parts

The Nash 904 vacuum pump has long been recognised as one of the most dependable liquid-ring vacuum pumps for demanding industrial environments. Designed for continuous operation, high moisture tolerance, and long service life, it has become a staple across industries where reliability, stability, and predictable vacuum performance are critical.

With more than 23 years of hands-on experience supporting Nash liquid ring vacuum systems, Airvac provides comprehensive lifecycle solutions for this platform. Our expertise spans rebuilding existing units, manufacturing drop-in replacement pumps, supplying spare parts, and delivering technical support for industrial and medical vacuum applications worldwide.

Whether you are operating an installed Nash 904 system, sourcing a cost-effective replacement, or extending the life of existing equipment, Airvac offers proven, engineering-led solutions built on decades of real-world experience.

What Is the Nash* 904 Vacuum Pump?

The Nash 904 is a single-stage liquid ring vacuum pump engineered for industrial processes that require consistent vacuum levels under harsh operating conditions. Its liquid ring design allows it to handle saturated gases, condensate, and process vapours without internal damage—making it particularly suitable for applications where moisture ingress would compromise other pump technologies.

Unlike dry-running or oil-sealed pumps, liquid ring vacuum pumps use a service liquid (typically water) to form a rotating ring inside the casing. This liquid ring creates compression chambers that generate a vacuum smoothly and reliably, even when process conditions fluctuate.

Over decades of use, the 904 platform earned its reputation for:

- Mechanical simplicity

- High tolerance to process contamination

- Long operational life

- Stable vacuum delivery in continuous-duty service

These characteristics have made it a preferred solution in industries where downtime is costly and process reliability is non-negotiable.

Nash* 904 Vacuum Pump Features

Its rugged construction and practical engineering define the 904 platform. Every aspect of its design focuses on durability, ease of maintenance, and predictable performance.

Key Design Features

-

Heavy-duty casing construction

Typically manufactured in cast iron, with stainless steel options available for corrosive or hygienic applications.

-

Single-stage liquid ring design

Delivers stable vacuum performance across a wide operating range.

-

Low internal wear characteristics

The absence of metal-to-metal contact significantly reduces wear during normal operation.

-

Excellent liquid handling capability

Ideal for processes with high moisture content, condensate, or vapour carryover.

-

Smooth, vibration-free operation

Liquid compression dampens mechanical shock and noise.

-

Continuous-duty capability

Engineered for 24/7 industrial service without performance degradation.

These engineering advantages explain why many original 904 units remain in service decades after installation.

Nash* 904 Model Variants

Over its lifecycle, the 904 platform has been supplied in several configurations to suit different process requirements and materials compatibility.

Common Variants and Configurations

- Standard 904 configuration

- Stainless steel construction for corrosive environments

- Rebuilt and refurbished units

- Custom configurations adapted to specific applications

Airvac supports both legacy units and modern equivalents through rebuild services and engineered replacement solutions.

Performance Specifications (General Range)

The Nash 904 vacuum pump operates within a well-established performance envelope suitable for medium to high-capacity industrial vacuum applications. While exact specifications vary by configuration, materials, and operating conditions, the table below outlines typical performance ranges.

Parameter | Typical Range |

Operating principle | Single-stage liquid ring |

Flow capacity | Medium to high industrial range |

Ultimate vacuum | Moderate to deep vacuum levels |

Motor power | Broad industrial horsepower range |

Operating speed | Fixed-speed industrial motor |

Service liquid | Water or compatible process liquid |

Connection sizes | Industrial flanged connections |

For precise performance data, Airvac engineers can match operating requirements to rebuilt or replacement units.

Common Applications

The Nash 904 platform is trusted across a wide range of industries where reliability, moisture tolerance, and continuous operation are essential.

Paper & Pulp Industry

Used extensively for:

- Sheet forming

- Dewatering

- Vacuum press sections

- Trim removal systems

Chemical & Pharmaceutical Processing

Ideal for:

- Filtration systems

- Solvent recovery

- Vapour handling

- Reactor evacuation

Food & Beverage Processing

Common applications include:

- Vacuum packaging

- Product transfer

- Evaporation processes

- Hygienic vacuum systems

Power Generation

Utilised for:

- Condenser exhausting

- Turbine vacuum support

- Auxiliary vacuum services

Mining & Metals

Supports:

- Gas handling

- Slurry dewatering

- Process vacuum applications

Medical Vacuum Systems

Applied in:

- Central medical vacuum plants

- Laboratory vacuum systems

- Hospital infrastructure

This versatility has helped cement the 904’s reputation as a dependable, multi-industry solution.

Rebuilt Nash* 904 Vacuum Pumps

Rebuilding remains one of the most cost-effective ways to extend the life of installed vacuum systems while restoring original performance.

Why Choose a Rebuilt 904?

- Significant cost savings compared to new OEM units

- Shorter lead times than factory-new equipment

- Performance restored to manufacturer specifications

- Reduced lifecycle costs without compromising reliability

- Sustainable reuse of existing assets

A professionally rebuilt pump delivers dependable service at a fraction of the capital investment required for new equipment.

Airvac Rebuild Process

Every rebuild is executed using a structured, engineering-led process designed to ensure reliability and repeatable performance.

1. Full Teardown & Inspection

- Complete disassembly of the pump

- Detailed inspection of casing, impeller, shaft, and internal components

- Identification of wear, erosion, and corrosion

2. Machining & Component Restoration

- Precision machining of critical surfaces

- Restoration of internal clearances

- Repair of eroded casings and cones

3. Component Replacement

- Bearings and seals replaced as standard

- Impeller refurbishment or replacement

- Shaft inspection and correction

4. Precision Balancing

- Dynamic balancing of rotating assemblies

- Vibration reduction for long-term reliability

5. Final Assembly & Testing

- Controlled reassembly to specification

- Performance testing under load

- Verification of vacuum level, flow, and mechanical integrity

AV-904: Drop-In Replacement for Nash* 904

For organisations seeking a modern alternative, Airvac manufactures the AV-904, a fully engineered drop-in replacement that matches or exceeds original performance.

Engineered Compatibility

The AV-904 is designed for:

- 1:1 dimensional compatibility

- Direct installation without system modification

- Equivalent or improved hydraulic efficiency

- Modern materials and manufacturing tolerances

Key Benefits

- Faster delivery compared to OEM lead times

- Available in cast iron or stainless steel

- Engineered for reliability in continuous service

- Backed by decades of liquid ring expertise

OEM Nash 904 vs Airvac AV-904

Feature | OEM Nash 904 | Airvac AV-904 |

Dimensional compatibility | Original | Direct drop-in |

Materials availability | Limited | Cast iron or stainless steel |

Lead time | Extended | Reduced |

Service support | OEM-dependent | Direct engineering support |

Lifecycle flexibility | Fixed | Rebuild or replacement options |

Nash 904* Spare Parts & Components

Maintaining performance over time requires access to high-quality replacement components. Airvac supplies a full range of spare parts compatible with the 904 platform.

Available Components

- Impellers

- Cones

- Bearings

- Shafts

- Mechanical seals

- Gland packing

- Casing components

- Gaskets and O-rings

All parts are manufactured or sourced to meet industrial durability standards, ensuring reliable operation and extended service intervals.

Common Issues the Nash* 904 Experiences

Even the most robust equipment can experience wear over time. Understanding common issues allows proactive maintenance and avoids unplanned downtime.

Typical Operating Challenges

- Loss of vacuum due to internal wear or seal degradation

- Overheating from insufficient service liquid or blocked flow

- Seal failure caused by age or process contamination

- Bearing wear from prolonged continuous operation

- Excessive vibration due to imbalance or misalignment

- Internal erosion in abrasive or corrosive processes

Addressing these issues early through rebuilds or component replacement significantly extends operational life.

Industries Served

Airvac supports vacuum systems across a wide range of industrial sectors:

- Paper & Pulp

- Chemical & Pharmaceutical

- Food & Beverage

- Power Generation

- General Manufacturing

- Medical & Healthcare Facilities

Each industry benefits from tailored solutions backed by deep application knowledge.

Model

Nash* | Airvac Equivalent | Suction | Discharge |

Nash* 904 L | AV-904 L | 10” Flange | 8” Flange |

Nash* 904 M | AV-904 M | 10” Flange | 8” Flange |

Nash* 904 P | AV-904 P | 12” Flange | 10” Flange |

Nash* 904 R | AV-904 R | 12” Flange | 10” Flange |

Nash* 904 S | AV-904 S | 14” Flange | 12” Flange |

Nash* 904 T | AV-904 T | 14” Flange | 12” Flange |

Nash* 904 U | AV-904 U |

|

|

Technical Details

Power Range: 125-800 HP

Capacity Range: 2000-12500 CFM

Max Vacuum: 26” Hg

Spare Parts

Frequently Asked Questions

What is the Nash* 904 used for?

It is widely used for industrial vacuum applications requiring continuous operation and moisture tolerance, including paper production, chemical processing, and power generation.

Is the Nash* 904 still available?

Original OEM availability may be limited, but rebuilt units and engineered replacements remain readily available.

Can a Nash* 904 be rebuilt?

Yes. Professional rebuilding restores performance and significantly reduces capital costs.

Do you offer replacement pumps?

Yes, the AV-904 is a direct drop-in replacement engineered for compatibility and reliability.

How does a liquid ring vacuum pump differ from other technologies?

Liquid ring pumps handle wet gases, vapours, and condensate without damage, offering smoother operation and higher tolerance than dry-running designs.

Are spare parts available?

A full range of spare parts and components is available to support maintenance and long-term operation.

Contact & Request a Quote

Whether you require a rebuilt unit, a replacement pump, spare parts, or technical advice, Airvac provides engineering-led solutions backed by decades of experience.

Our technical team is ready to help you select the most reliable, cost-effective solution for your vacuum system requirements.